FIG 145

The Fabricast FIG-145 is a unique high performance polymer lined bi-directional drip tight knife gate valve. Designed and tested to mss sp81 and asme b16.5 specifications.

The Fabricast FIG-145 is a unique high performance polymer lined bi-directional drip tight knife gate valve. Designed and tested to mss sp81 and asme b16.5 specifications.

Features

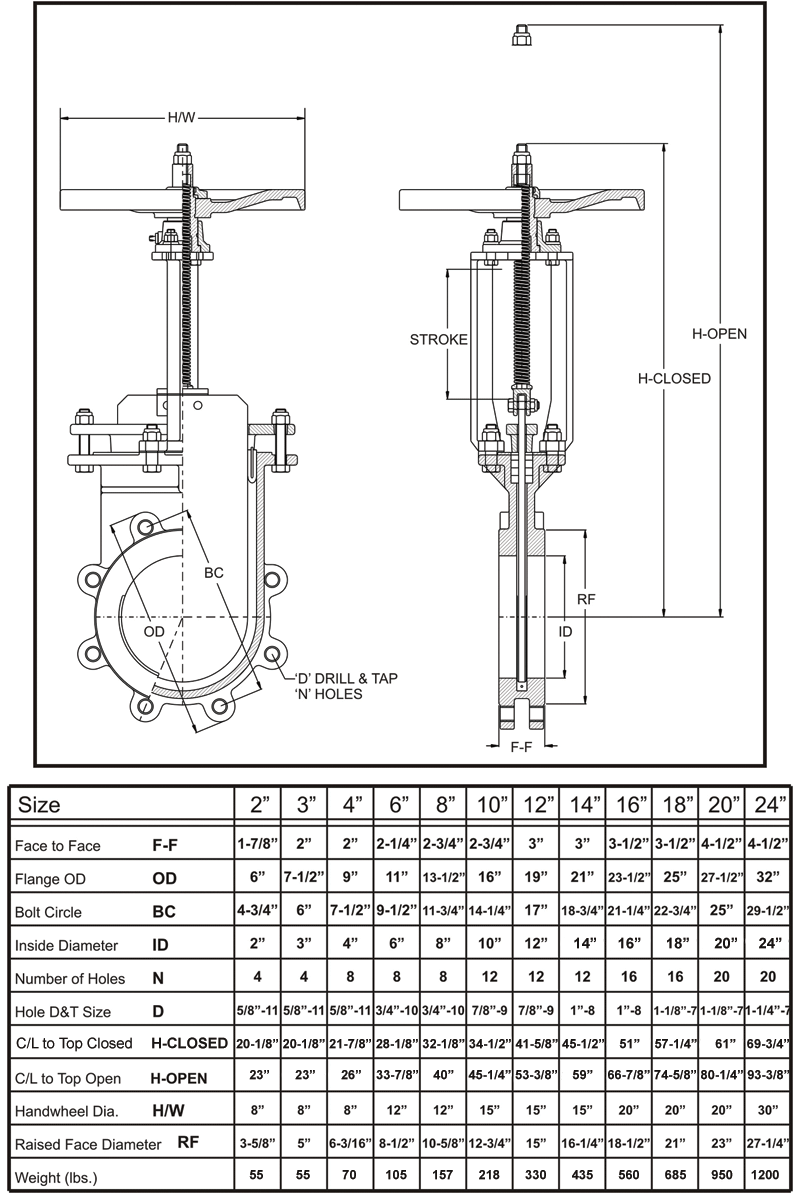

- Heavy duty fabricated ASTM A36 Carbon Steel body, packing gland and yoke. Standard size range is 2″- 48″

- 3 piece replaceable polymer liners. UHMWPE (ultra high molecular weight polyethylene) is standard rated to 180 deg F. The seat insert is a T shape that mechanically locks it into the liners. The liners and seat insert are sealed to the valve body with a special silicone sealant preventing the flow media coming in contact with the valve body. The full length body liners support the gate throughout the full stroke preventing deflection and premature packing wear. The packing chamber in the valve body is extra deep utilizing several rows of braided packing resulting in a superior atmospheric seal.

- 304 stainless steel fixed retaining rings are standard

- Full port

- 150 psi cwp rated – see FIG 345 for higher pressure

- Precision cnc machined valve body and stem

- ASTM a 240 304 stainless steel gate fully machined and surface ground. All edges are chamfered to extend packing life and to provide a superior atmospheric seal.

- 14″ and larger valves are supplied with a ball bearing yoke bushing to reduce handwheel rimpull

- Braided teflon synthetic packing is standard 3-11 ph rating

- Locking fasteners are standard on all fabricast valves

- Cast WCB steel handwheel (weldable)

- Easily adapted to air cylinder, hydraulic cylinder, bevel gear, lever or electric motor operator (no welding required)

Options

- Liners/insert – Polyurethane 180 Deg F, Polypropylene 225 Deg F, High temp UHMWPE 280 Deg F, Teflon 400 Deg F, Other – contact factory.

- Other alloys – 304, 316, 317l, duplex 2205, 2507,904l, Hastelloy, Titanium Other – contact factory

- Mechanical lockouts – manual and actuated valves

- OSHA gate guard

- Pneumatic, hydraulic and spring cylinder, electric motor operator, 3:1 and 4:1 bevel gear operator, chainwheel, stem extensions, lever operator

- Packing – PTFE, graphite, kevlar, food grade, other – contact factory

- Purge / flushing ports

- Limit / proximity switches, solenoid valves, positioners, air sets, speed controls, exhaust mufflers, air tank failsafe systems, air boosters

- V port insert for flow control

- Deflector cones for abrasive service

- Replaceable abrasion resistant and hardened retaining rings

- Seat cavity filler

- Specialty exterior coatings

- Bonneted design

- Slide gate design – FIG 202

- Ni-resist alloy stemnut

- Live loaded packing system

- Specialty gate coatings

- Hardsurfacing for abrasive service

PREVIOUS MODEL FV-150-LKG