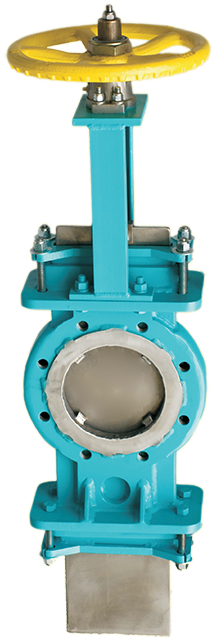

FIG 215

The Fabricast FIG 215 is a metal seated, uni-directional o-port slide gate valve. Designed and tested to MSS SP81 and ASME B16.5 specifications. For use in heavy solids flow media – hd stock, powders, hopper bottoms or anywhere a cutting action is required to close the valve.

The Fabricast FIG 215 is a metal seated, uni-directional o-port slide gate valve. Designed and tested to MSS SP81 and ASME B16.5 specifications. For use in heavy solids flow media – hd stock, powders, hopper bottoms or anywhere a cutting action is required to close the valve.

Features

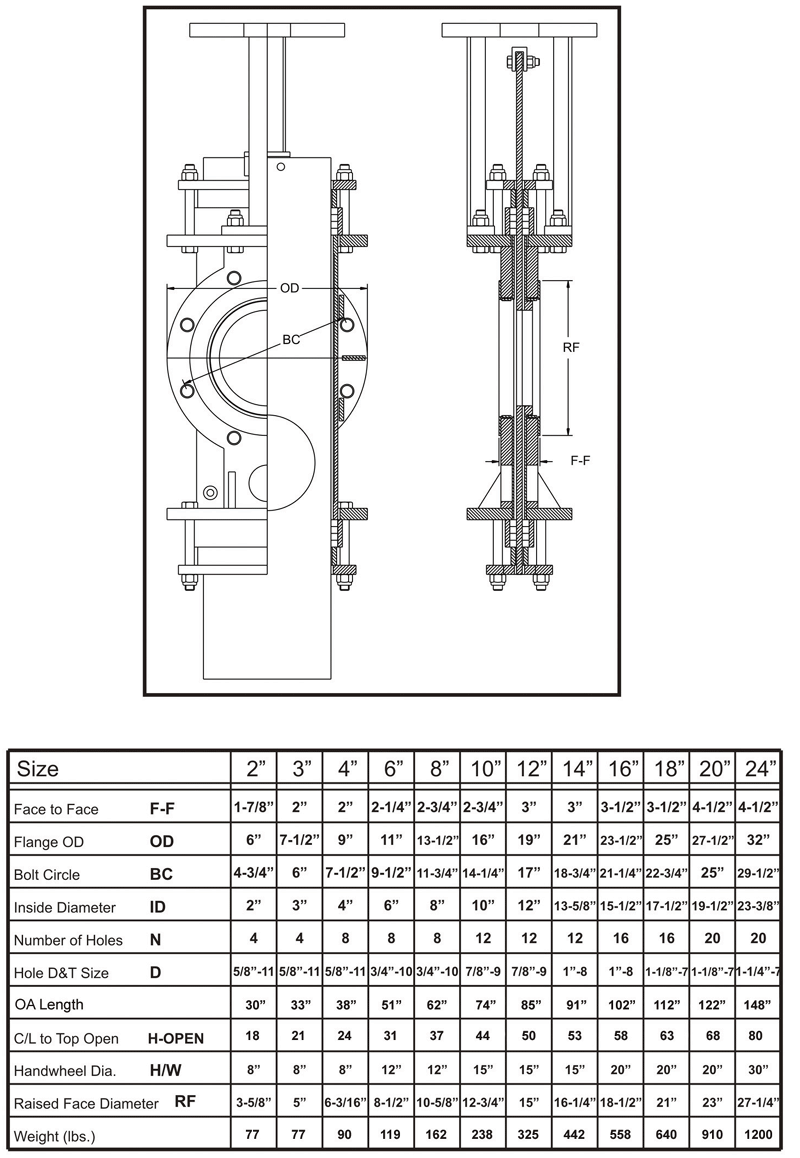

• Heavy duty fabricated and welded carbon- stainless steel body 2″ – 48″, packing gland, yoke, stemnut retainer and gate clevis. Sizes larger than 24″ are available in a fabricated and welded design.

• Full Port.

• 150 PSI CWP rated.

• Precision CNC machined valve body and stem

• ASTM a 240 304 stainless steel o-port gate fully machined and surface ground. All edges are chamfered to extend packing life and to provide a superior atmospheric seal.

• 14″ and larger valves are supplied with a ball bearing yoke bushing to reduce handwheel rimpull

• Braided teflon synthetic packing is standard. 3-11 PH rating.

• Cast WCB steel handwheel (weldable).

• Easily adapted to air cylinder, hydraulic cylinder, bevel gear, lever or electric motor operator (no welding required).

Options

• O-Ring seat – BUNA N 200 deg. F. EPDM 300 deg. F. HDPE / uhmwpe 200 deg. f, FKM/VITON – 400 deg F.

Other – contact factory.

• Other Alloys – CS, 304, 310, 316, 317l, Duplex 2205, 2507, 904l, Hastelloy, titanium other – contact factory.

• Mechanical lockouts – manual and actuated valves

• OSHA gate guard

• Pneumatic, hydraulic and spring cylinder, electric motor operator, • 3:1 and 4:1 bevel gear operator, chainwheel, stem extensions, lever operator

• Packings – ptfe, graphite, kevlar, food grade, other – contact factory

• Purge / flushing ports

• Limit / proximity switches, solenoid valves, positioners, air sets, speed controls, exhaust mufflers, air tank failsafe systems, air boosters

• V port for more precise flow control

• Deflector cones for abrasive service

• Ni-resist alloy stemnut

• Live loaded packing system

• Specialty gate coatings

• Hardsurfacing for abrasive service

• Backing ring for reverse flow or horizontal valve orientation

• Bonneted design

• High pressure / High temperature

PREVIOUS MODEL FV-150-SG